WHAT’S THE DIFFERENCE BETWEEN DTG VS DTF VS SILK SCREEN?

| DTG (Direct-to-Garment) | DTF (Direct-to-Film) | SILK SCREEN (Screen Print) | |

|---|---|---|---|

| WHAT IS IT? | Works like your desktop printer, but instead of paper, you print on the garment | The design is printed onto a special film, which is then transferred onto the garment using a heat press machine | Ink is forced through silk screens onto the garment |

| STEPS | 1) Pre-treatment is applied to the garment to prevent ink from being absorbed into the garment 2) Garment is cured for the first time with a heat press 3) Garment is placed on platen and goes through the printer 4) A second curing occurs so the ink stays durable | 1) Design is printed onto the transfer film 2) Ink on film is coated with adhesive powder so it can be glued onto the garment 3) Film is heat pressed onto the garment | 1) Creating a screen from a stencil, where the areas which the color will be applied are opened 2) The screen is put into place on the garment and each color of ink is pushed through the screen with a squeegee, onto the layered surface of the garment 3) The garment goes through curing |

| INK | ·Uses water-based ink and CMYK colors ·Ink goes directly into the fabric fibers ·Uses more colored ink | ·Uses water-based ink and CMYK colors ·Ink goes directly onto the film ·Uses more white ink as it has to be the base | ·Traditionally, plastisol inks are used and can be mixed to match Pantone shades ·You can also use discharge and water-based inks |

| FABRICS | ·Better suited for cotton, bamboo, linen ·Not as compatible on polyester or other synthetic fabrics ·A white ink base color is needed for dark colored fabrics ·Print color is as is ·Because ink is sprayed directly onto the garment, the color may be less vibrant | ·Works on both natural fabrics as well as synthetics ·White ink needs to be added as a base for both light and dark colors | ·Works on most fabrics ·Works on non-fabrics like plastics and metals ·Great for printing bright colors onto dark ground ·No base needed ·Print color is as is |

| PRINT QUALITY | ·High quality and full multi-color ·Depending on the fabric color, some print colors will differ from the actual design ·Good for complex designs and photorealistic images ·Great at color blending ·Consistency of print is good (some color variance may occur) | ·Vibrant and vivid colors ·Better suited for few colors or flat designs like logos ·You will feel the film on your body for larger designs ·Consistency of print is great | ·Very bright and bold colors ·Best for designs with few colors, as each color is its own screen ·Can print fluorescent and metallic colors ·Not suited for detailed designs ·Not ideal for color blending, but can be imitated using halftone technique called “simulated process” ·Has inconsistency with each print because of many factors (eg screen movement, ink viscosity, dry temp, pressure and angle, etc) |

| PRINT POSITIONING | ·Limited to the front, back and sometimes sleeve patterns of the garment | ·Because you’re printing onto the film and depending on the size of the design, you could customize where you would like to hear press and place the print on the garment (eg neck. armhole) | ·Can be printed at different locations as long as the screen can be positioned |

| WASHING & DURABILITY | ·Print can usually last up to 20-30 washes with care ·But if you’re opting for a vintage look, you can keep washing the garment and that effect will naturally occur ·Because ink penetrates the fabric fibers, it becomes part of the garment ·Over time the print will slowly crack | ·Film can begin to peel after many uses ·After a few washes, the print will be smoother ·Powder residue will dissolve ·More resistant to cracking ·Preferred choice for activewear garments that undergo frequent stretching and movement | ·Print usually lasts longer than DTG and DTF ·With water-based inks, the print will slowly fade with washing ·Over time the print will crack, chip and peel away when using plastisol inks |

| HANDFEEL & COMFORTABILITY | ·Softer and more breathable ·Print is part of the fabric so you almost don’t feel it on you ·DTG feels better on the skin because the ink is sprayed directly onto the garment | ·Has a plastic feel ·Print lays on top of the fabric ·The powder adhesive used for DTF can feel thick and heavy ·If the print is large, you will definitely feel it on you | ·Plastisol ink will typically lay heavier on garments ·Water-based ink will have a softer handfeel |

| SPEED | ·Relatively fast (this is also dependent on factors like quantity, how fast the steps are followed, design size and quality, etc) ·Can print one-offs easily ·Better suited for small to medium order quantities | ·Relatively fast (this is also dependent on factors like quantity, how fast the steps are followed, design size and quality, etc) ·Can print one-offs easily ·Good for medium to large orders | ·Slow if individually done by hand ·Faster once automated machines are set up ·Set up process takes time ·Not ideal for small orders or one-offs ·Good for medium to large orders |

| SUSTAINABILITY | ·No film needed | ·PET film is needed ·Uses more white ink than DTG | ·Hazardous chemicals and toxic fumes ·Non-recyclable materials |

| COST | ·Ink is expensive ·No setup fee | ·Ink is more affordable than DTG ·Transfer film and adhesive powder are affordable ·No setup fee | ·Ink is considerably affordable ·Setup is costly and time-consuming since one stencil is one color |

| MISCELLANEOUS | ·Designs can be printed and cut for future use or resold ·DTF can be used on non-garments like coffee mugs, laptop covers, etc | ·Can print on a variety of surfaces like pens, water bottles, etc |

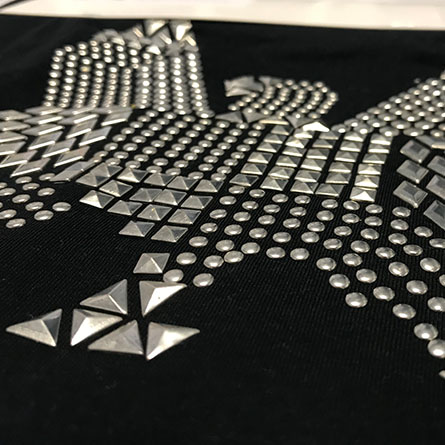

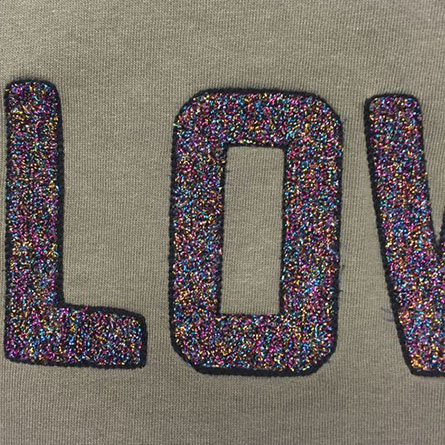

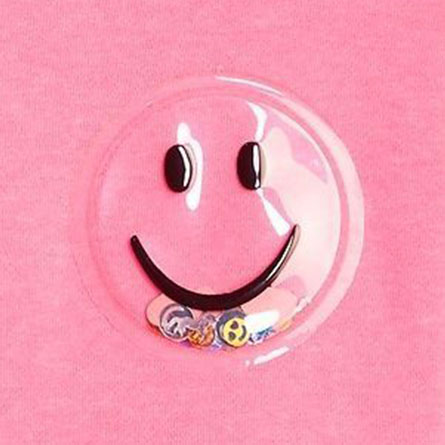

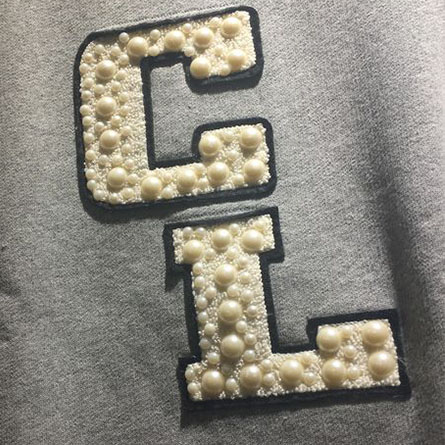

HERE ARE EXAMPLES OF PRINTING TECHNIQUES YOU SHOULD BE FAMILIAR WITH TO ELEVATE YOUR MERCH.

Check with your local printer if they’re able to execute these techniques or you can always get in touch with me and I’ll help you get started!

(PLASTISOL INK)

(WATER BASED INK)

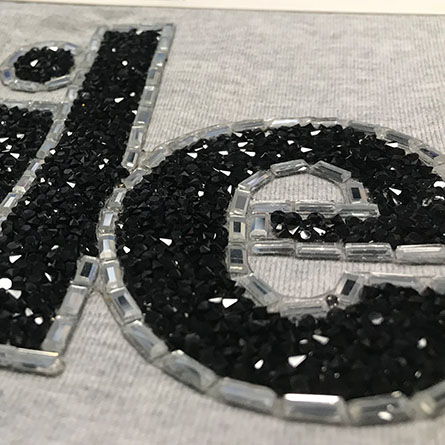

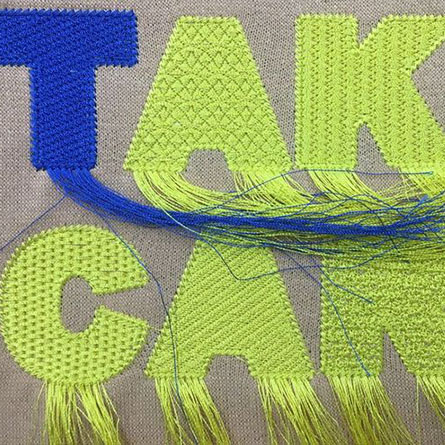

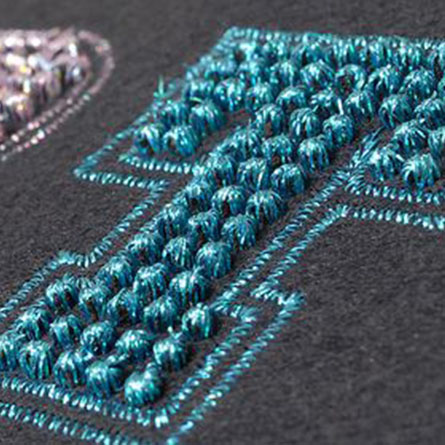

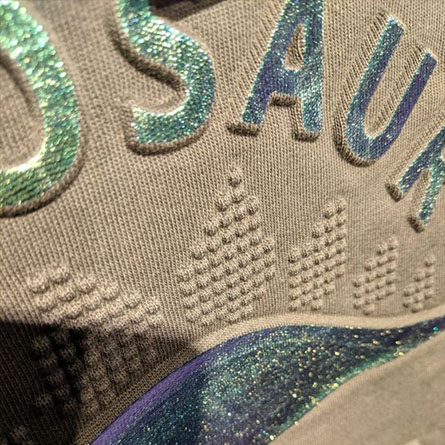

OTHER COOL TECHNIQUES

Contact me and let’s see what we can do for you!